BLAST CHILLING: A CRITICAL CONTROL IN THE PREPARATION OF FOOD

Time and temperature relationships are critical to the growth and spread of contamination, contributing to sensory-quality and safety loss in foods. Every food-service manager is aware of this fact, and of how difficult it can be to make all food-service employees use safe food handling and storage practices in an attempt to prevent quality loss and possible food-borne illness.

With operator awareness and regulatory agency surveillance, why has there been a general increase in national incidence of food-borne illness - illness that could be controlled by use of proper food handling temperatures? Temperature control, especially cold storage, is an often misunderstood and neglected control point in the safe preparation and holding of food. The standard recommendation for rapid cooling of prepared food is the use of a two-inch product depth and a cumulative time of four hours or less in the 140�F-45�F (60�C-7.2�C) "danger zone." Ironically, the following chart illustrates how long it actually takes to properly cool prepared foods in 2", 4" and 6" (50.8mm, 101.6mm and 152.4mm) deep pans, stored in a 38�F/3.3�C standard storage refrigerator. Top

1. Cooling Times (in Hours) in Standard Walk-in

| Food Product | 2" Deep Steam Table Pan |

4" Deep | 6" Deep |

| Beef Stew | 12 hrs. | 16 hrs. | 22 hrs. |

| Chicken and Turkey a la King | 10 hrs. | 14 hrs. | 22 hrs. |

| Swiss Steak with Tomato Sauce | 13 hrs. | 17 hrs. | 20 hrs. |

| Sliced Beef and Gravy | 10 hrs. | 13 hrs. | 23 hrs. |

| Gravy | 11 hrs. | 14 hrs. | 21 hrs. |

| Broth | 5 hrs. | 8 hrs. | 12 hrs. |

| Cream of Pea Soup | 10 hrs. | 13� hrs. | 18 hrs. |

| Mashed Potatoes | 12 hrs. | 16 hrs. | 22 hrs. |

| Peas | 6 hrs. | 9 hrs. | 13 hrs. |

| Broccoli | 7 hrs. | 9� hrs. | 14 hrs. |

| Lasagna | 11 hrs. | 17 hrs. | 21 hrs. |

Consider the consequences if prepared foods are contaminated by the following organisms and are cooled as slowly as Chart 1. shows.

| Organisms | Temperature | Generation Time (Min.) |

| Escherichia coli | 98.6�F/37�C | 17 min. in broth 12.5 min. in milk |

| Salmonella typhi | 98.6�F/37�C | 23.5 min. in broth |

| Staphylococcus aureus | 98.6�F/37�C | 27-30 min. in broth |

| Streptococcus lactis | 98.6�F/37�C | 48 min. in broth 26 min. in milk |

The air blast chiller provides critical temperature control during conventional food preparation. The blast chiller is more efficient in cooling foods than the standard storage refrigerator.

To understand the basic principle of the blast chiller, let us review its conception. Initially, the blast chiller was designed to support cook/chill programs where foods were prepared or cooked, rapidly cooled through the 140�F-45�F "danger zone," and held in refrigerated inventories to be reheated and served later. Rapid cooling prolonged the safe storage life of these foods.

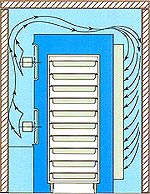

Since the standard storage refrigerator is designed to hold foods that are already chilled, it is ill-equipped to effectively remove heat from loads of prepared foods placed inside it. Hence the blast chiller was developed, offering greater heat removal capacity and utilizing high-velocity, convected air directed through the product zone to promote fast, even cooling of foods. The rapid temperature pull-down accomplished by these systems proved to extend safe storage life and improved the quality of the food.

The following chart illustrates the cooling time of similar product loads; one placed in the blast chiller and the other in a standard storage refrigerator. Note the cooling curves for the center of the food mass and air temperature recovery times.

As these illustrate, the blast chiller provides the critical control necessary in properly cooling and holding prepared foods. Unfortunately, the blast chiller is seldom considered for its value in functioning as a much-needed control point in conventional food preparation programs.

Conventional storage refrigerators are not engineered and equipped to remove the heat rapidly from a large load of hot food. Consequently, several hours are required to reduce product temperatures through the temperature danger zone, a situation which could result in loss of product quality and sanitation. The Northwind is Engineered to remove the heat rapidly using High-Speed Laminar Air Flow. Top

WHAT IS A CONVENTIONAL FOODSERVICE PROGRAM?

This question is part of today's food safety problem. Historically, conventional food preparation meant preparing food for immediate service with brief hot and cold holding periods involved. In order to survive, today's food-service operations are anything but conventional.

Common operational pressures include a limited supply of skilled labor, escalating overhead, insurance and construction expenses, competition forcing menu expansion in kitchens originally not designed for producing multiple menu items, and attempts to build profitability through satellite, banquet, and catering functions. These are but a few factors creating havoc in today's conventional food-service kitchens.

Few operators are able to prepare foods for immediate service. Items are produced several hours before consumption, often allowed to cool at room temperature or placed into standard storage refrigerators -- refrigeration systems that cannot cool foods safely.

The following microbiological data are the result of an unstructured test analyzing the effect of cooling time on the condition of sliced turkey and gravy prepared in a high school kitchen. Product was prepared conventionally, sliced, placed in sanitized 12" x 10" x 2-1/2" (304.8mm x 254mm x 63.5mm) steam table pans and covered with aluminum foil. Each pan was filled to a depth of two inches; total product weight was six pounds. Product compared was from the same production batch. The blast-chilled product load required 2 to 3-1/2 hours to cool from above 140�F (60�C) to a central core temperature below 45�F (7.2�C); the product load cooled in the standard storage refrigerator required six to eight hours. Upon subsequent storage in a 38�F (3.3�C) holding refrigerator, standard plate count tests illustrated an average of over 100,000 aerobic organisms per gram of product sampled by day three in the storage refrigerator cooled turkey and gravy. Top

| Time Following Chilling | Chill Processing Refrigerator | Holding Refrigerator |

| Initial | 3,000 | 4,000 |

| Day 3 | 8,000 | 151,000 |

| Day 7 | 400 | 5,700 |

| Day 10 | 4,500 | 30,000 |

| Day 14 | 13,000 | 40,000 |

Adding to public health concern is the fact that minimal heat treatment is applied when these foods are reheated in an attempt to maintain food quality after they have been improperly cooled and stored. Top

Bally Northwind blast chillers are designed to provide that critical control necessary to maintain food quality and sanitation during the preparation of a wide range of foods in today's busy food-service kitchens.

The Bally Northwind blast chiller is a versatile, multi-use system that supplements the cooling demands being made on today's conventional food storage systems. It controls microbial contamination and food deterioration by rapid product cooling through the 140�F-45�F (60�C-7.2�C) "danger zone" for food handling, effectively preparing foods for subsequent safe storage in holding refrigerators. Top

Charts